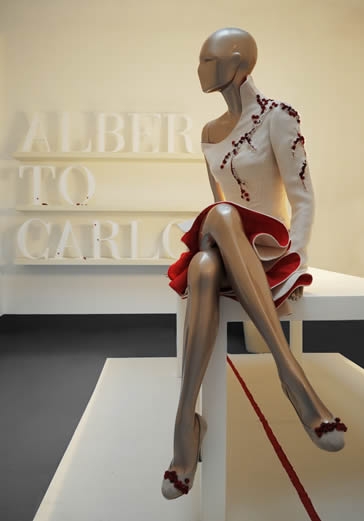

Dossier magazine: Sculptures for high fashion

Modena, Italian city and birthplace to prestigious exotic car companies such as Lamborghini, Maserati and Pagani. The city is also home to another field which is experiencing enormous success in many parts of the world. “The vicinity to automotive manufacturers of such incredible importance has allowed us access to the best in paint and color technologies with top professional craftsmanship for our mannequins which undergo the same identical painting process as the exotic luxury cars. The use of precious paints makes our mannequins even more unique and exclusive.” explains Alain Leporati, owner of King Manichini.

How does the inspiration come to begin specializing in something like mannequins?

“Our company set out at the end of the ’80’s when the city of Carpi was living its magical moment with its main industry strongly rooted in clothing and knitwear. We initially produced custom sartorial busts which were created for the various companies based on the measurements desired by the most demanding fashion designers, we then extended our production to the world of retail with men’s and women’s busts which were created specifically with the display window in mind.

Then in 2000 there was literally an “economic boom” in mannequins which we had not seen in the stores since the 1970’s, it was at that time that we specialized in full body mannequins.”

Your company is quite active with its international business. Which are the main countries you export to and what are the numbers?

“65% of our production is sold internationally with the remaining 35% for the domestic market. The markets which have awarded us most are the Middle Eastern countries, Eastern Europe, and the Western European countries. We have experienced a slower pace with sales to the Unied States due to the exchange rate which has been so unfavorable between our Euro and the U.S. dollar. At the same time however, we have done business in places which we least expected like Kazakhstan, Tanzania, and Azerbaijan.”

Which materials are used to create your mannequins and what types of craftsmanship is needed to attain the finished product?

“A truly incredible variety of materials is used to create our mannequins and busts, materials like fiberglass, kevlar, stainless steel, wood, leather, all types of fabrics, and innovative materials as well such as our ‘carta stratificata’ and special paints. All raw materials are scrupulously selected and to date we have not made any compromises.

No element in our production is brought in from the Far East. The only importation we have is from Switzerland and regards our neodymium magnets which are used in our patented shoulder attachments. This is just another aspect which sets us apart from our competitors even when we are talking about practicality.”

A core aspect of your products is represented by the aesthetics and the care you dedicate to detail.

“Like in all fields, a project stems from an idea. The idea is developed by creating a real sculpture which becomes a statue that then must be cut in order to allow dressing. We have always strived to reduce these cuts to an absolute minimum as they subtract from the overall elegance of the mannequin, so we avoid cuts at the waist and wrists. Once we finish this stage we begin creating the actual mold which will be needed for production. Even though a mold is used, the application of the fiberglass is carried out completely by hand and once the mannequin is out of the mold many, many hours are still needed in order to move on to the painting process. After the multilayer painting process is carried out the mannequin is ready to undergo the application of a series of elements which bring it to completion.”

How are you able to guarantee the uniqueness and at the same time the quality of the product? How do you work under this point of view?

“Every item which comes out of our production is always unique due to the artisanal craftsmanship. Every stage of production is entrusted to team members who are specialized in that particular field and when the product is completed it must then undergo final testing and quality control. We also give great attention to packing materials and this is an important part of quality for us because we need our products to arrive to their destinations safe and sound. Given that most of our shipments are destined outside the country we use custom built boxes made to our specifications in high resistance vulcanized cardboard which is closest to strength to wood, the boxes are lined with thick styrofoam, and we use a lot of maxi bubble wrap to protect our paint finishes from any bumps. All of this generates extra costs but special attention is necessary to guarantee quality in every regard. The production cycle isn’t completed for us until the mannequins have arrived in perfect condition and are safely in their display windows.”